OSHA's New Confined Space Standard

It is generally agreed that this new standard was written to mirror many facets of its general industry counterpart.

- By Chris Irwin, Jessica Smith

- Jul 01, 2015

Since it was issued in 1993, OSHA's confined space regulation, 29 CFR 1910.146, has been geared toward general industry workers, with very little applying directly to the construction industry. Employers in the industry have tended to default to general industry standards but have not had a substantial regulation of their own to fall back on. On Aug. 3, 2015, however, the OSHA confined spaces in construction standard, 29 CFR Subpart AA 1926.1200, joined the existing general industry confined space standard and clearly defined rules for confined spaces in construction. It is estimated that this move can prevent roughly 780 serious injuries and five deaths each year.1

At a confined spaces press conference on May 1, 2015, Dr. David Michaels, assistant secretary of Labor for OSHA, stated, "This rule will save lives of construction workers. Unlike most general industry work sites, construction sites are continually evolving, with the number and characteristics of confined spaces changing as work progresses."2 He added that "all workers have the right to a safe and healthy workplace, and it only makes sense that all workers have similar protections when working around the same hazards."3

Confined Space vs. PRCS

First, let's define a confined space. A confined space is a space large enough for a worker to enter, is not designed for "continuous employee occupancy," and has limited means for entry and exit.4 A permit-required confined space (PRCS) is a confined space with one or more of the following characteristics:

- Contains or has a potential to contain a hazardous atmosphere

- Contains a material that has the potential for engulfing an entering employee

- Has an internal configuration such that an employee could be trapped or asphyxiated by inwardly converging walls or by a downward-sloping floor

- Contains any other recognized serious safety or health hazard5

Common Hazards

The new rules aim to reduce the risks presented by hazards common to confined spaces in the construction industry, such as oxygen deficiency and the presence of explosive or toxic gases, vapors, or fumes. Examples of confined spaces include condenser pits, manholes, ventilation ducts, tanks, sumps, and containment cavities, among many others.6 Hazards can be controlled by locking out moving parts, de-energizing electrical parts or wiring, blocking steam pipes and product in-feeding pipes, draining or pumping out liquid contents, or air monitoring and ventilating.7

Similarities and Differences in the Standards

How does 29 CFR 1926.1200 differ from general industry standards? It is generally agreed that this new standard was written to mirror many facets of its general industry counterpart. Construction entities that currently implement and comply with the general industry standard will have a strong basis for compliance to the new standard. That stated, there are several differences from the general industry standards that are discussed below.

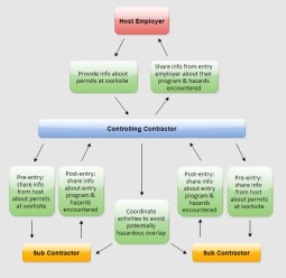

The updated confined spaces rules include more specific provisions for requiring coordinated activities when multiple employers are on the same work site. These provisions are intended to ensure that hazards are not introduced into a confined space by an employee working on a different project or task nearby. The general industry standard required communication and coordinated activities, but the nature of a construction site with its larger number of contractors makes the dynamic of that coordination somewhat different. (See the flowchart below.)

At a construction site, a host employer (the owner of the site) is added to the mix of parties in communication. Prior to entry operations, the host employer must provide information to the controlling contractor on the location and potential hazards of any known confined spaces, as well as any precautions implemented for employee safety. The controlling contractor must then share that information with each entity entering the space or that could potentially introduce a hazard into the space. Each entry employer (subcontractor) should then inform the controlling contractor of the permit space program it plans to follow and any hazards likely to be confronted. The controlling contractor is then responsible for coordinating the activities of entry employers when multiple entities are either in the same space or their activities might conflict and introduce a hazard. After entry operations, the controlling contractor must debrief each entity that entered the permit space regarding the program followed and any hazards encountered. The controlling contractor must then provide the information gathered to the host employer.8

The new standard also includes a "competent person" clause. The general industry rule required that the employer evaluate the work site and identify confined spaces. The new construction standard instead requires evaluation by a "competent person," perhaps a supervisor, and potentially multiple persons.9

Additionally, the new regulation allows for the mere suspension of a permit rather than a mandated cancellation if a condition not allowed under the entry permit arises with the permit space, so long as the condition is temporary in nature, does not change the configuration of the space, or create any new hazards within it.10

The Part 1926 standard also encourages continuous atmospheric monitoring where possible. The general industry standard required only periodic monitoring and never attached a timing requirement. It is noted that if the employer can demonstrate that periodic monitoring is sufficient, OSHA does not require continuous monitoring.11 However, continuous monitoring is always best practice.

In the new standard, OSHA requires that employers implement an early-warning system that continuously monitors for non-isolated engulfment hazards, such as flash flooding.12

Finally, employers are required to provide safety training in a language and vocabulary that workers understand.

Does This Affect You?

The new confined spaces standard applies to anyone doing construction with the exception of excavations, underground construction, caissons, cofferdams, compressed air, and diving, as specified in the law. If a company is engaging in both construction and industrial work and meets the criteria of 29 CFR 1926.1200—Confined Spaces in Construction, the employer should be in compliance.13

Employers' Action Steps

Faced with new OSHA regulation, an employer's action steps should begin with a determination of whether the regulation is relevant, i.e. whether there is a confined space at a work site. If there are one or more confined spaces that include existing or potential hazards, the employer must classify the space accordingly.

In conclusion, the new OSHA confined spaces in construction standard will have wide-reaching effects on the construction industry and the safety of its workers. Dr. Michaels stated that the rule "emphasizes training, continuous work site evaluation and communication requirements to further protect workers’ safety and health."

Organizations planning to take on a construction project need to be well informed about the impacts of the new regulation and how to adjust their processes in order to remain in compliance. This article serves as a summary of the new standard. Further details on the standard in its entirety, compliance assistance documents, and other resources to help employers and workers understand the rule can be found on OSHA's Confined Spaces page: www.osha.gov/confinedspaces/.

References

1. United States Department of Labor, Press Teleconference on Confined Spaces: Remarks Prepared for Delivery by Dr. David Michaels, https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=SPEECHES&p_id=3379. (May 28, 2015)

2. United States Department of Labor, OSHA Confined Spaces Frequently Asked Questions, https://www.osha.gov/confinedspaces/. (May 28, 2015).

3. https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=SPEECHES&p_id=3379.

4. https://www.osha.gov/confinedspaces/.

5. OSHA Confined Spaces in Construction standard, 29 CFR Subpart AA 1926.1200, p. 6, https://www.osha.gov/confinedspaces/1926_subpart_aa.pdf

6. Jeffrey Dalto, Update from OSHA Spokesperson on Publication of Upcoming Confined Spaces in Construction Standard (1926.1200), Convergence Training Blog, http://blog.convergencetraining.com/update-from-osha-spokesperson-on-publication-of-upcoming-confined-spaces-in-construction-standard-1926-1200 (May 29, 2015).

7. Occupational Safety and Health Division of North Carolina, Confined Spaces Training, https://www.env.nm.gov/Ohsb_Website/Training/documents/ConfinedSpaces.ppt (June 6, 2015).

8. Ibid pp. 12-14

9. Ibid p. 8

10. Ibid p. 19

11. Ibid p. 10

12. Ibid p. 16

13. https://www.osha.gov/confinedspaces/

This article originally appeared in the July 2015 issue of Occupational Health & Safety.